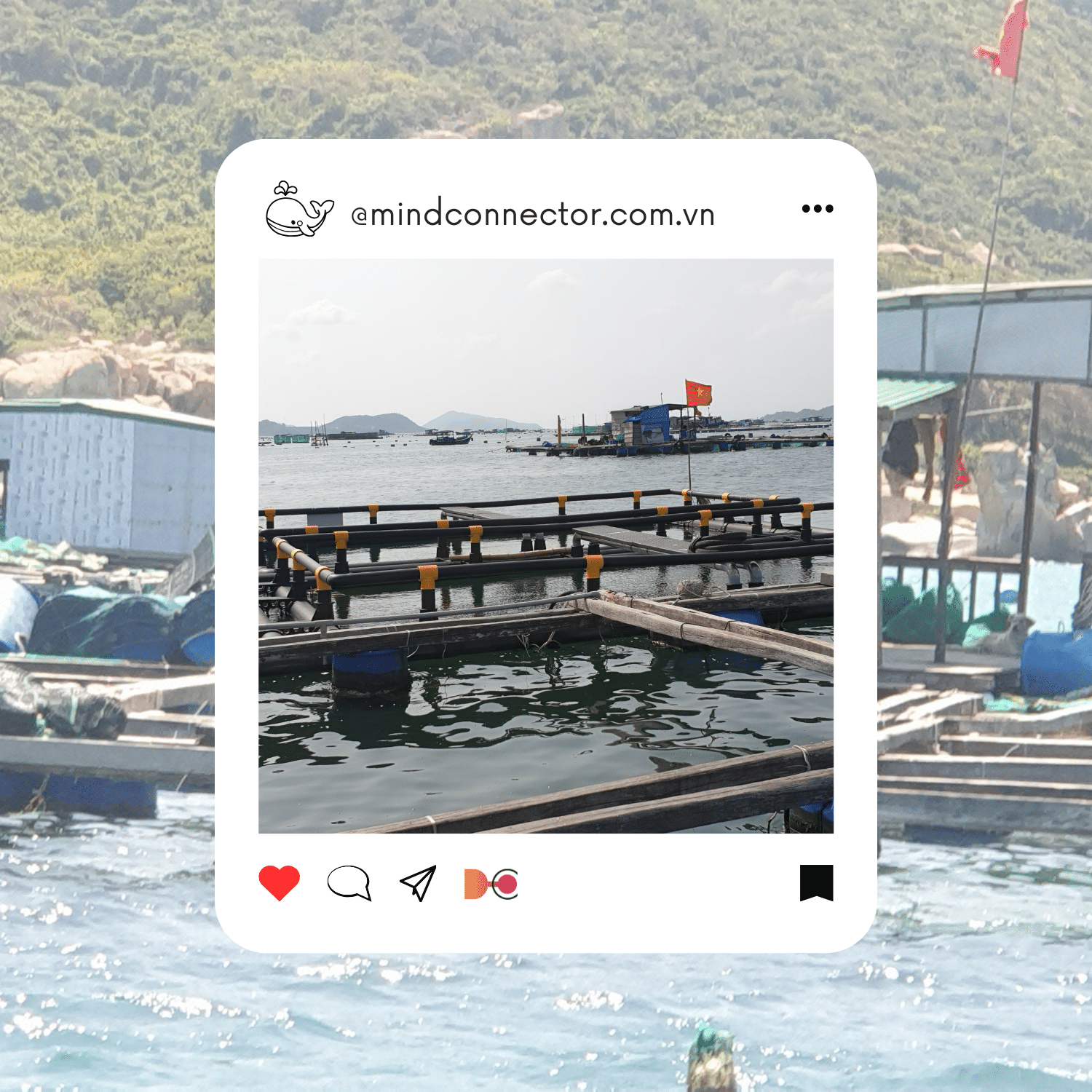

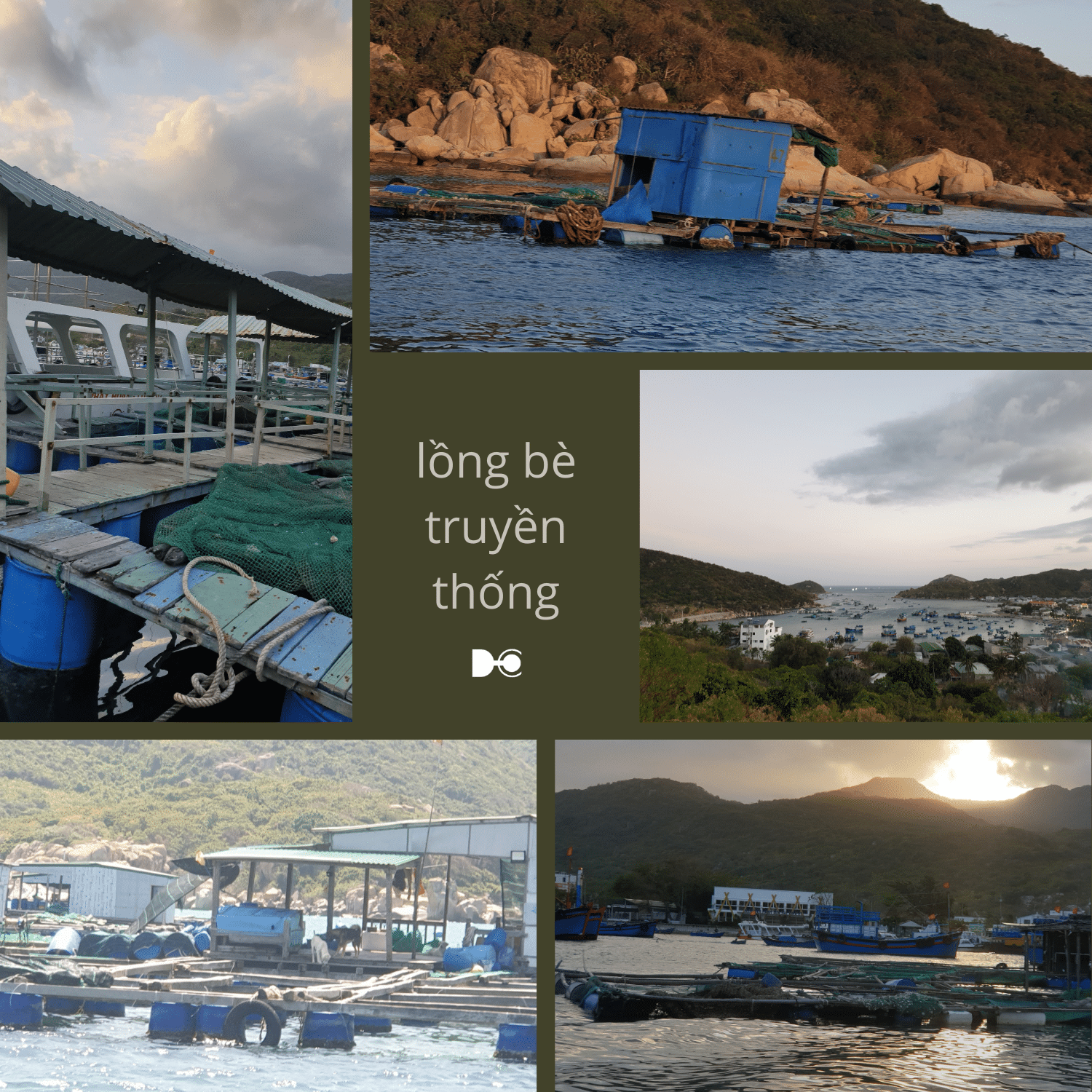

In the context of the strong development of the sustainable marine aquaculture industry, the conversion from traditional cages to cages using HDPE (High-Density Polyethylene) is not only an inevitable trend but also a long-term sustainable solution. However, few people know that HDPE cage products in Vietnam have gone through a long journey from learning from advanced countries to the challenging localization efforts of domestic enterprises.

Learning from the predecessors

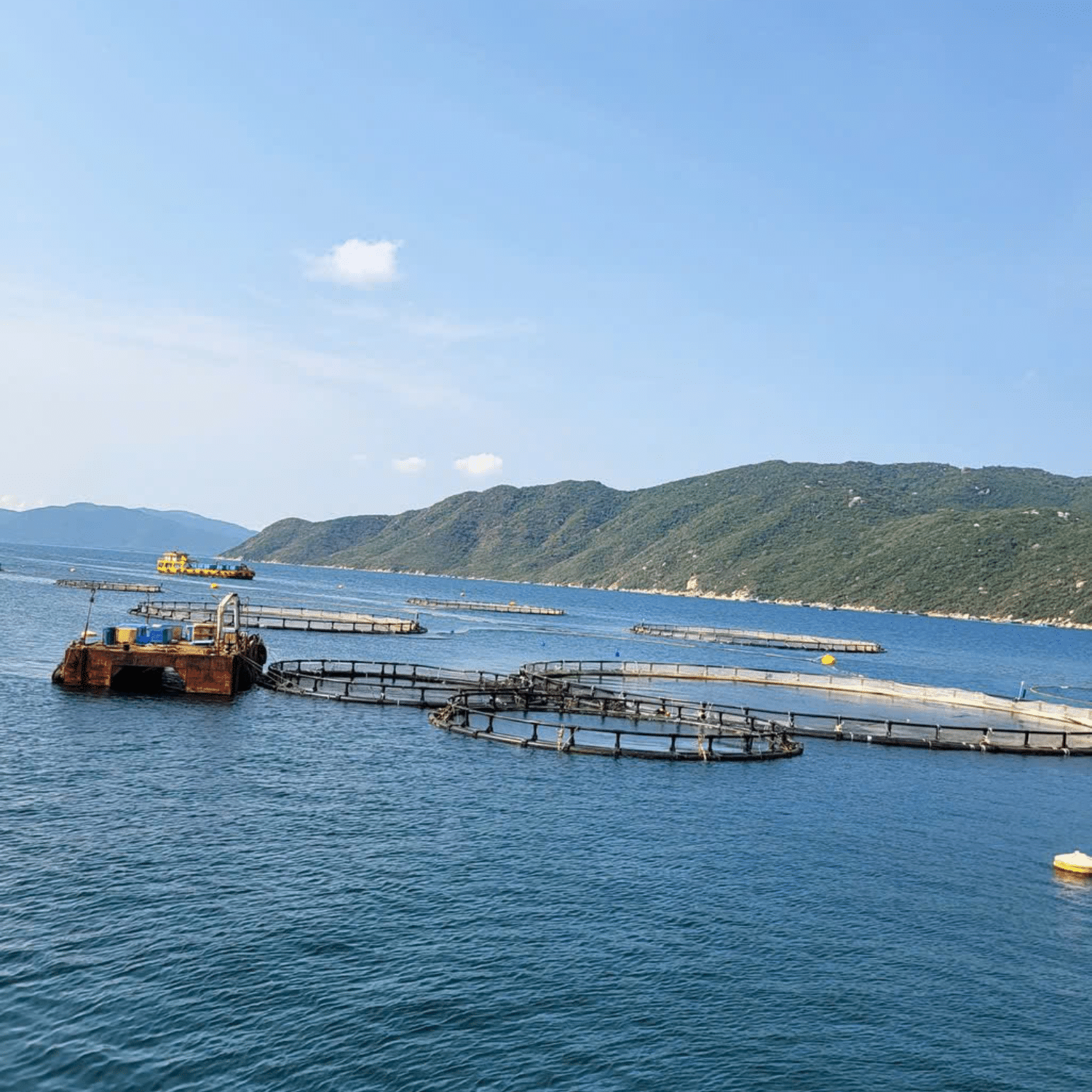

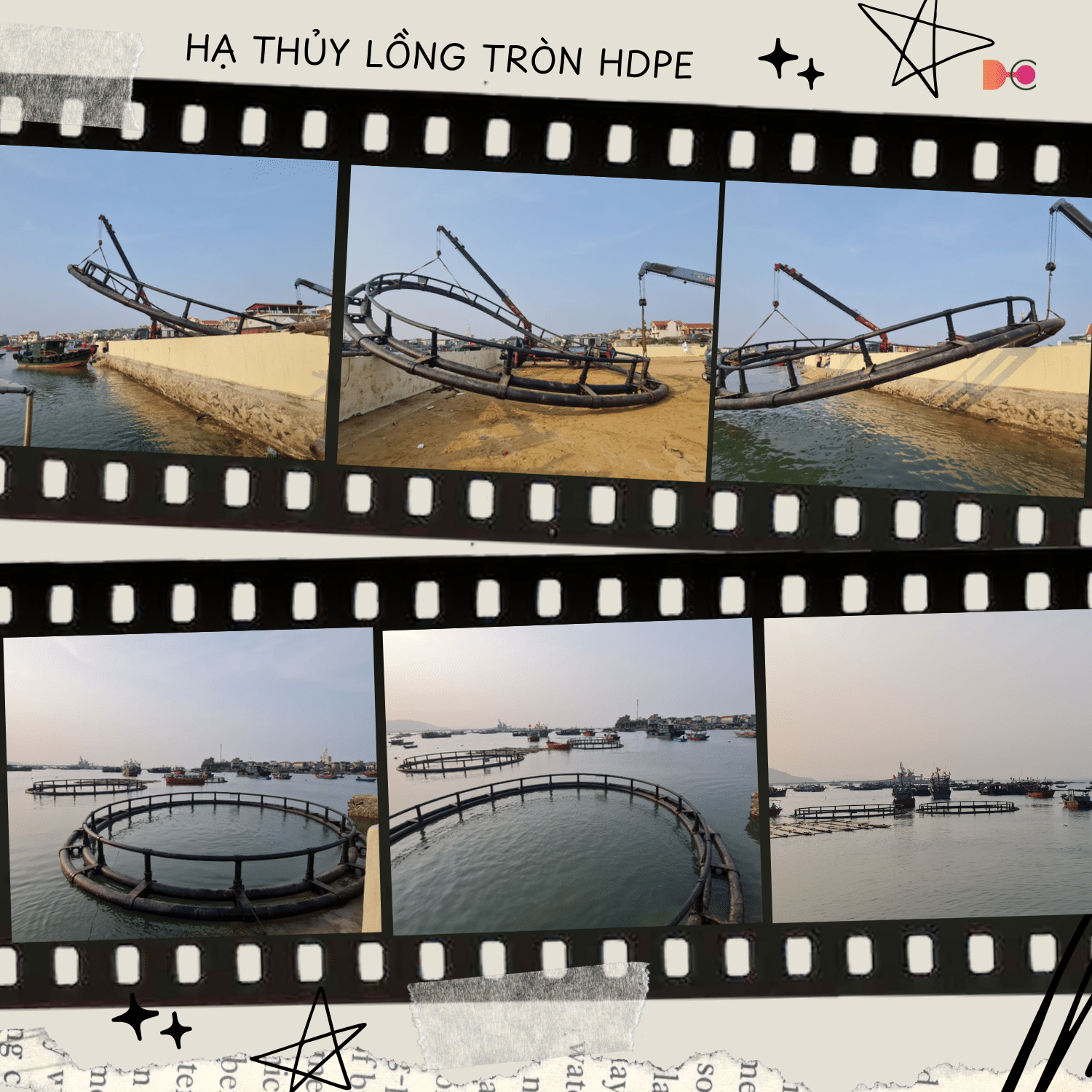

Countries with developed marine aquaculture industries such as Norway, Australia, and Chile have used HDPE cages since the 1990s. These models were born to solve the problem of durability, safety, and protection of the marine environment. HDPE cages have a lifespan of 15-20 years, can withstand harsh marine conditions, are not corroded by salt water, and minimize risks from natural disasters.

Recognizing these outstanding advantages, a number of large enterprises in Vietnam have proactively approached the technology and researched and deployed HDPE cages. Initially, most HDPE materials had to be imported from Europe at high costs. Installation and operation also encountered many difficulties due to lack of technical expertise and practical experience.

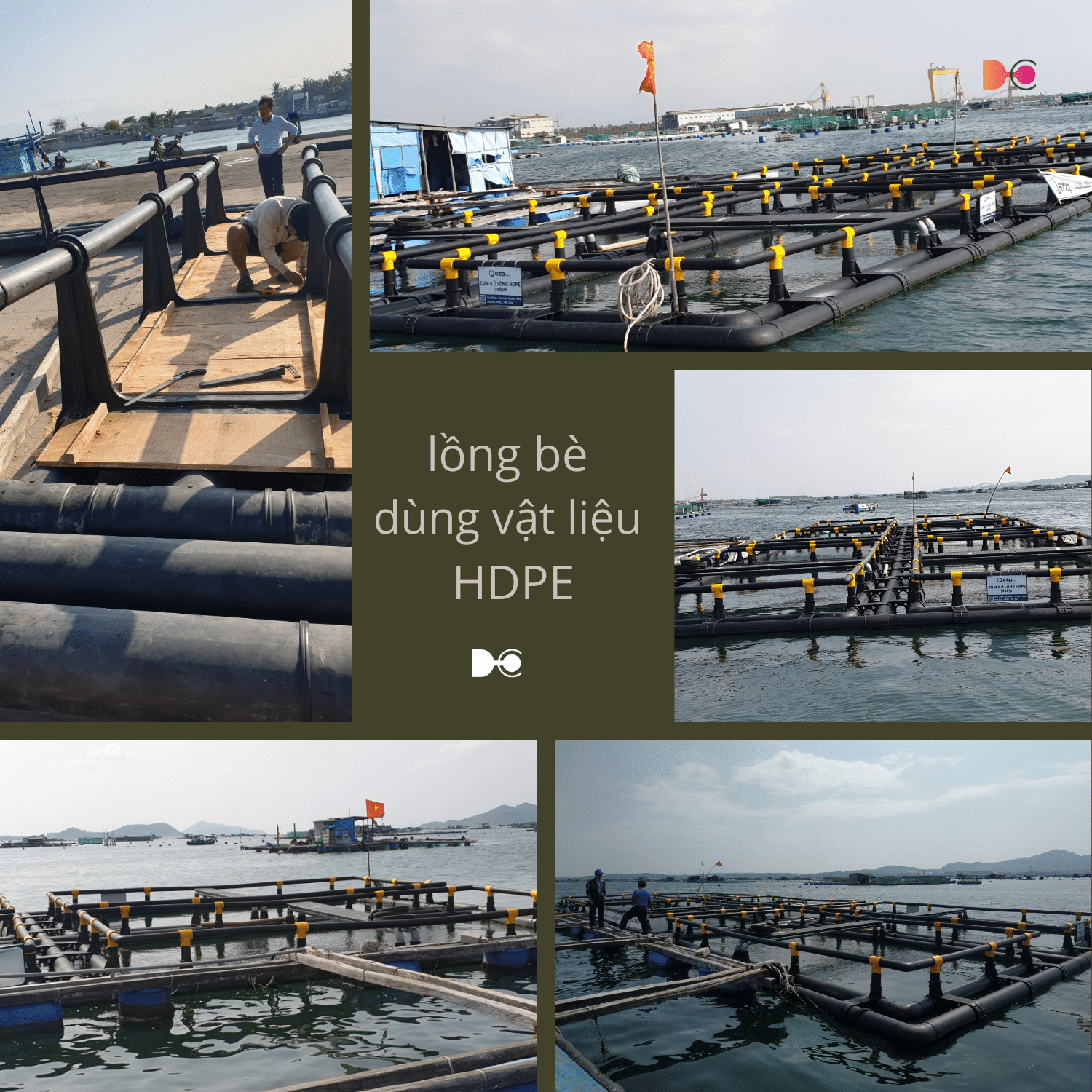

The challenging localization process

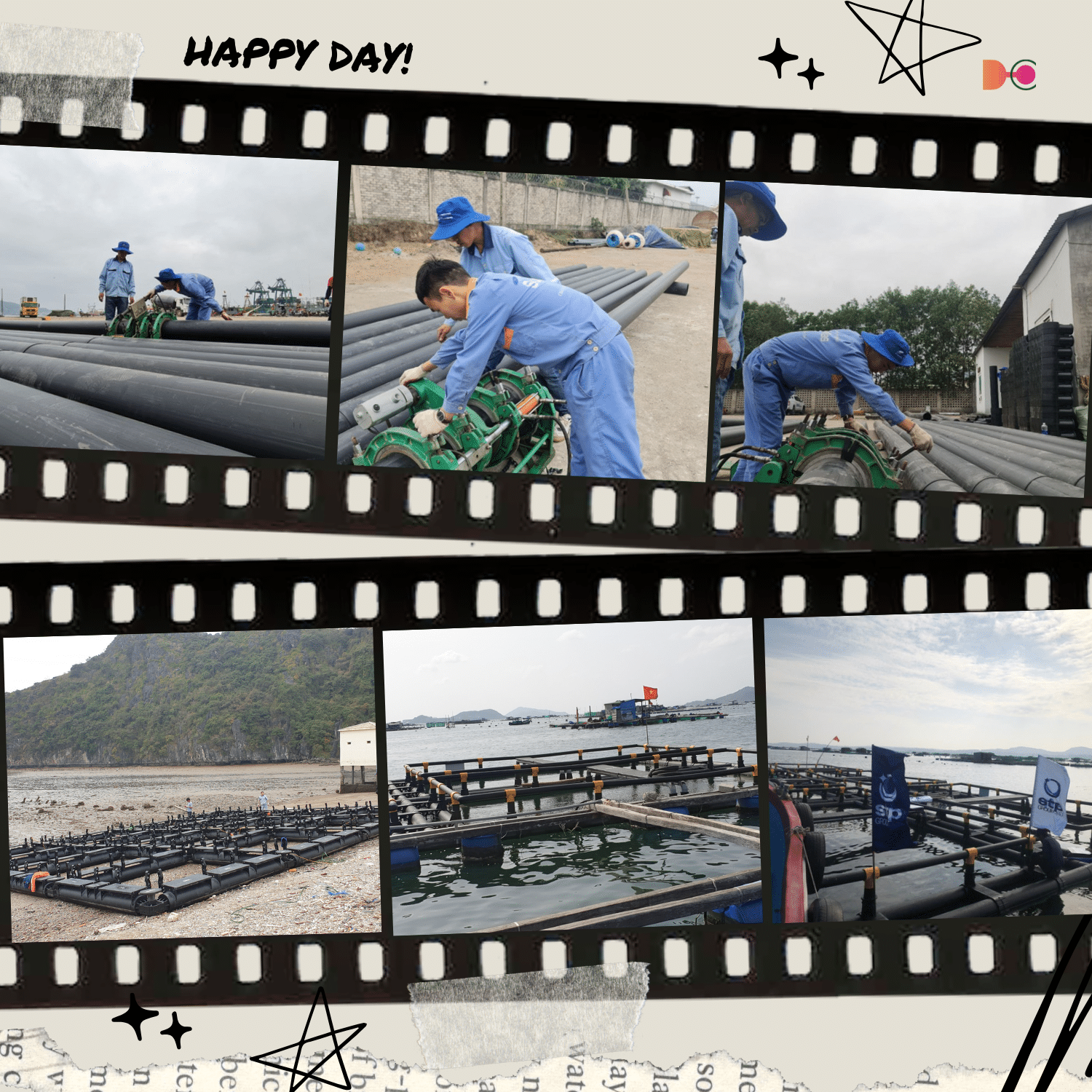

Since 2015, as the demand for sustainable marine farming has increased, Vietnamese enterprises have begun to focus on localizing HDPE products. Despite many challenges, pioneering units such as STP, Tien Phong, Hoa Sen … have made significant progress:

- Proactively source raw materials: Invest in HDPE pipe production lines that meet international standards, gradually reducing dependence on imported goods.

- Design improvement: Adjust the cage structure to suit the conditions of Vietnam’s sea.

- Reduce production costs: Increase production scale to optimize costs, bringing prices to a more reasonable level for farmers.

However, the initial investment cost for an HDPE cage is still 3-4 times higher than that of a traditional cage, making it difficult for many people to access even if they want to.

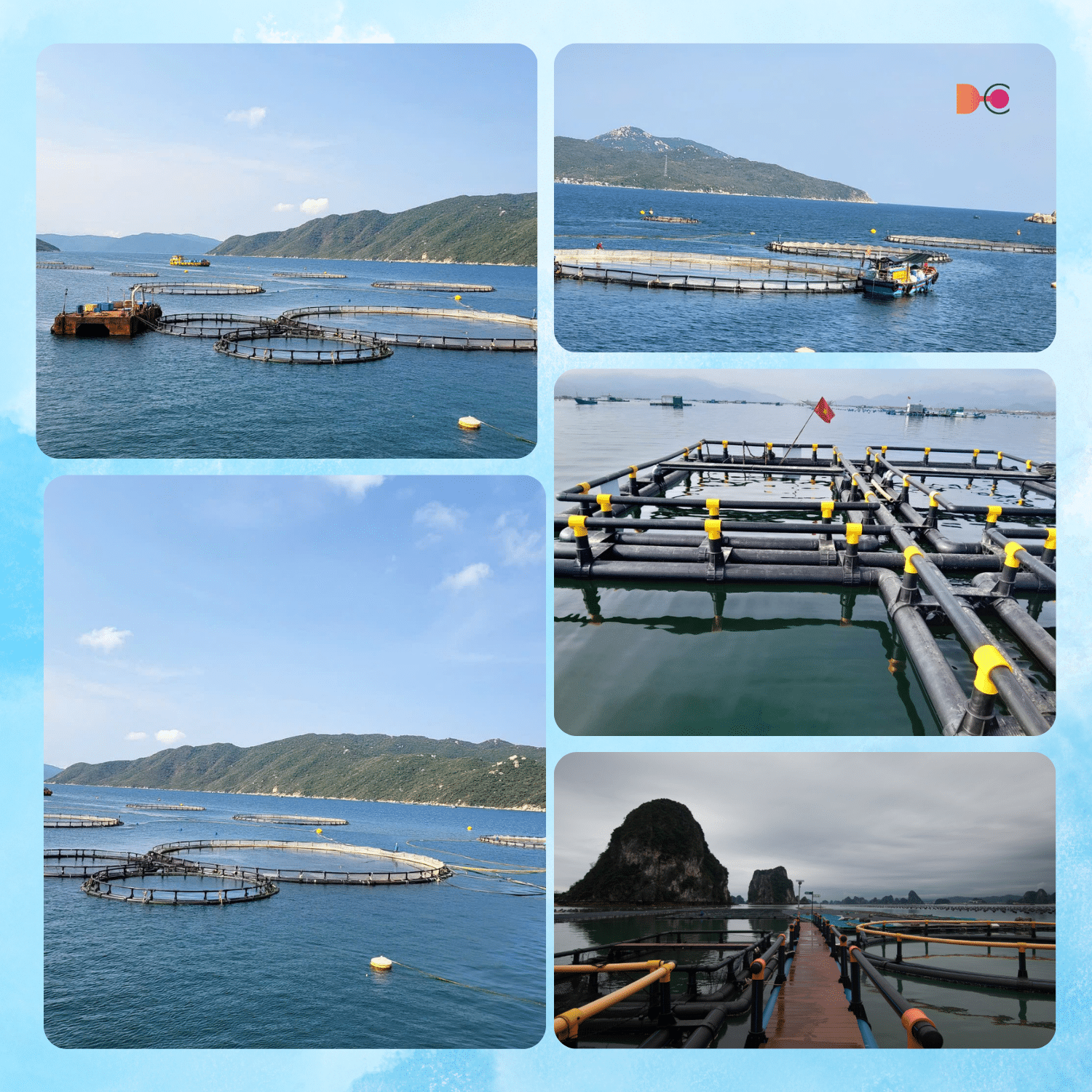

Ecosystem Linkage – Solution to Unblocking the Knot

To solve the cost problem and expand the scale of using HDPE cages, there needs to be close cooperation between stakeholders:

- Linking material manufacturers: Enterprises producing plastic pipes and outdoor plastic panels need to coordinate to create a complete product set, minimizing intermediate costs.

- Public-private partnership: Authorities and enterprises need to coordinate to build financial support programs, preferential loans or long-term installments to make it easier for people to convert.

- Pilot model: Build sample HDPE cage models in key farming areas, helping people clearly see the effectiveness and gradually replicate it.

Directions for HDPE cages in Vietnam

In reality, large enterprises are currently not interested in the HDPE cage market due to low profits and small scale. Meanwhile, small enterprises, although enthusiastic, face difficulties in capital and production capacity. To change the situation, there needs to be a leading unit, ready to invest long-term and connect components in the supply chain.

If all parties join hands, the journey from learning to localization will no longer be a distant dream. HDPE cages will become a sustainable solution, opening up a new future for Vietnam’s marine aquaculture industry – a future in which both fishermen and businesses benefit fairly and sustainably.