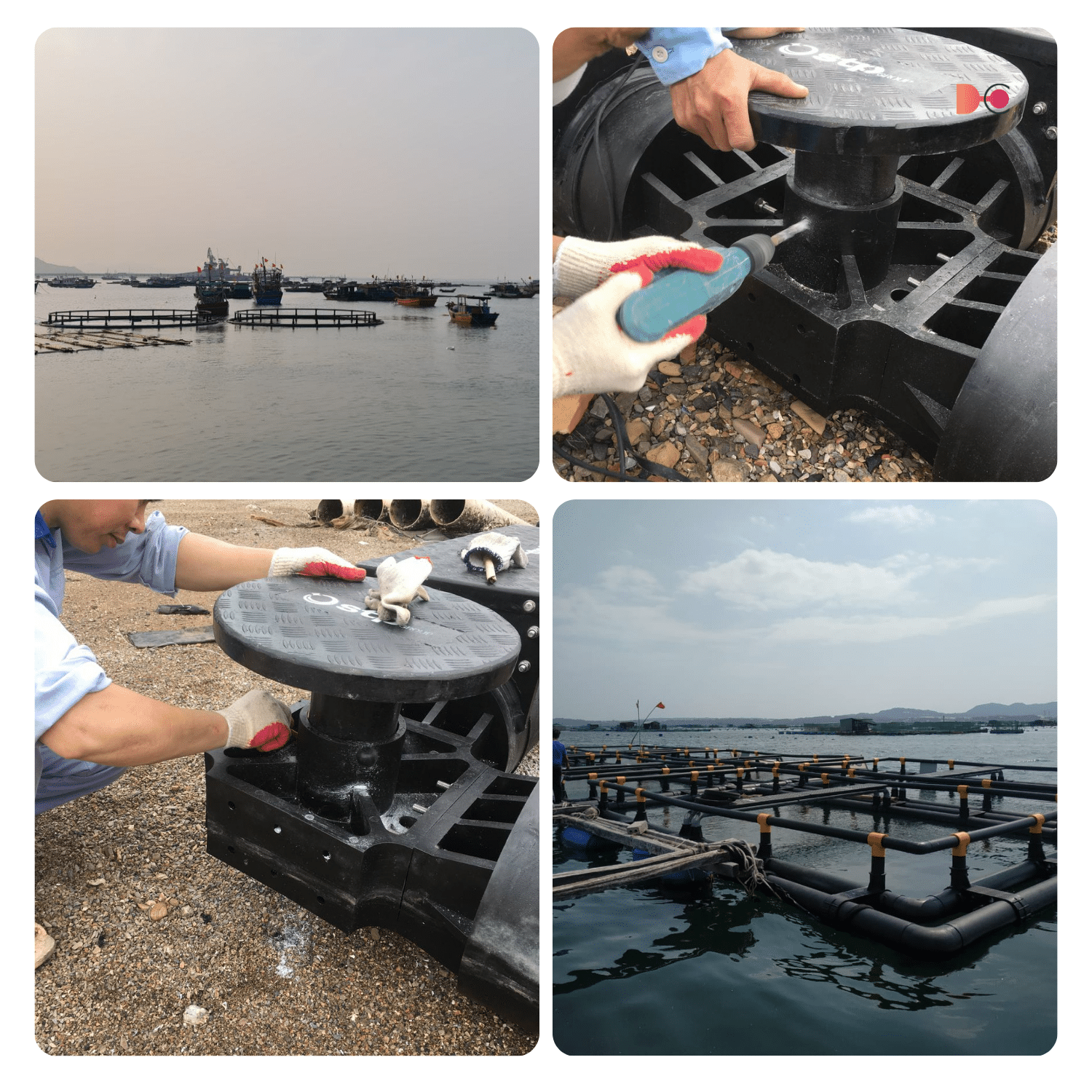

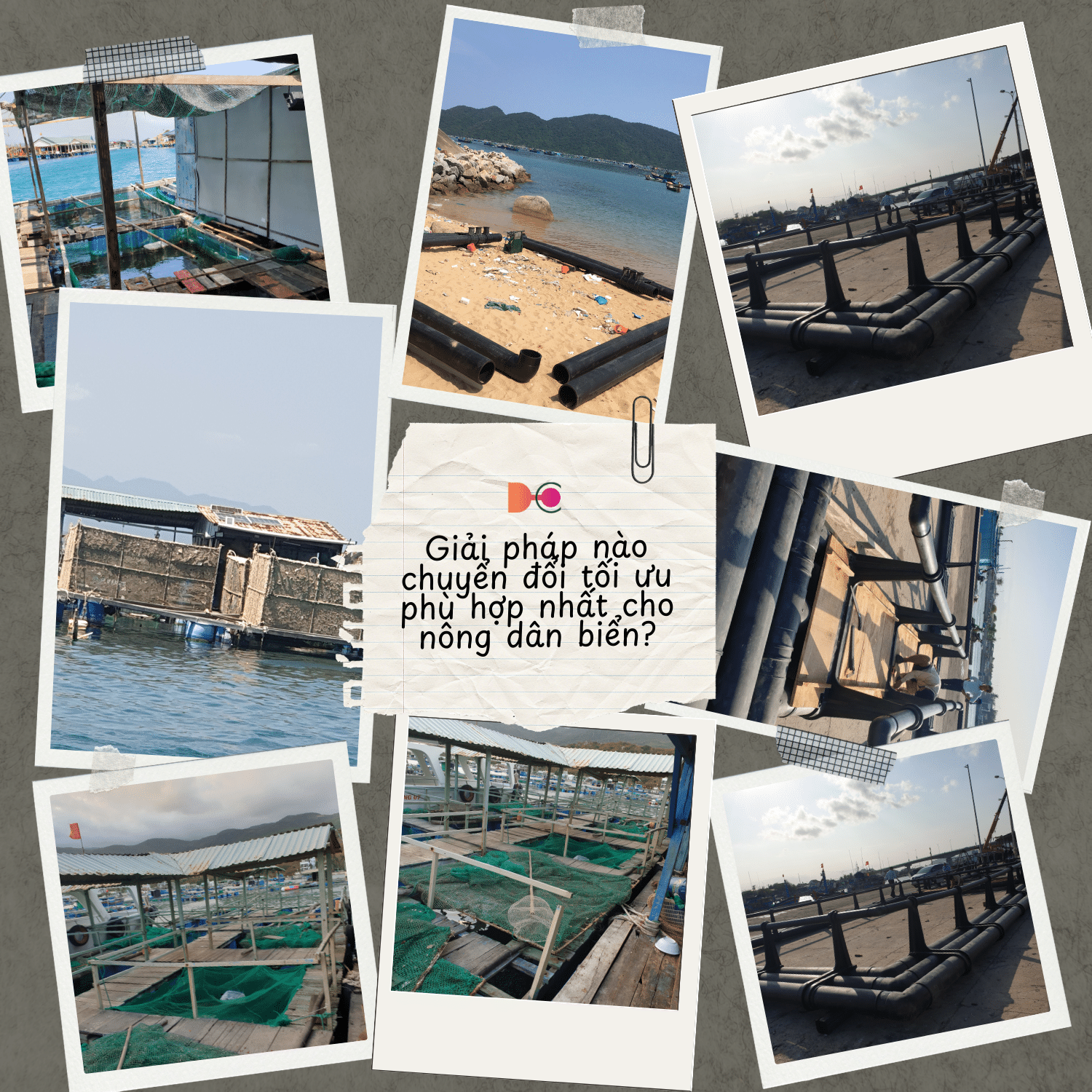

In recent years, sustainable marine aquaculture has become an important goal for the Vietnamese aquaculture industry. However, despite being aware of the long-term benefits of HDPE (High-Density Polyethylene) cages, many fishermen still face difficulties in converting due to the high initial investment costs.

While a traditional cage made of plastic and bamboo costs only about 15 million VND, the cost of an HDPE cage is up to 50 million VND or more. The question is: What should businesses do to support people to overcome cost barriers and promote the conversion process?

Conversion is difficult due to high costs

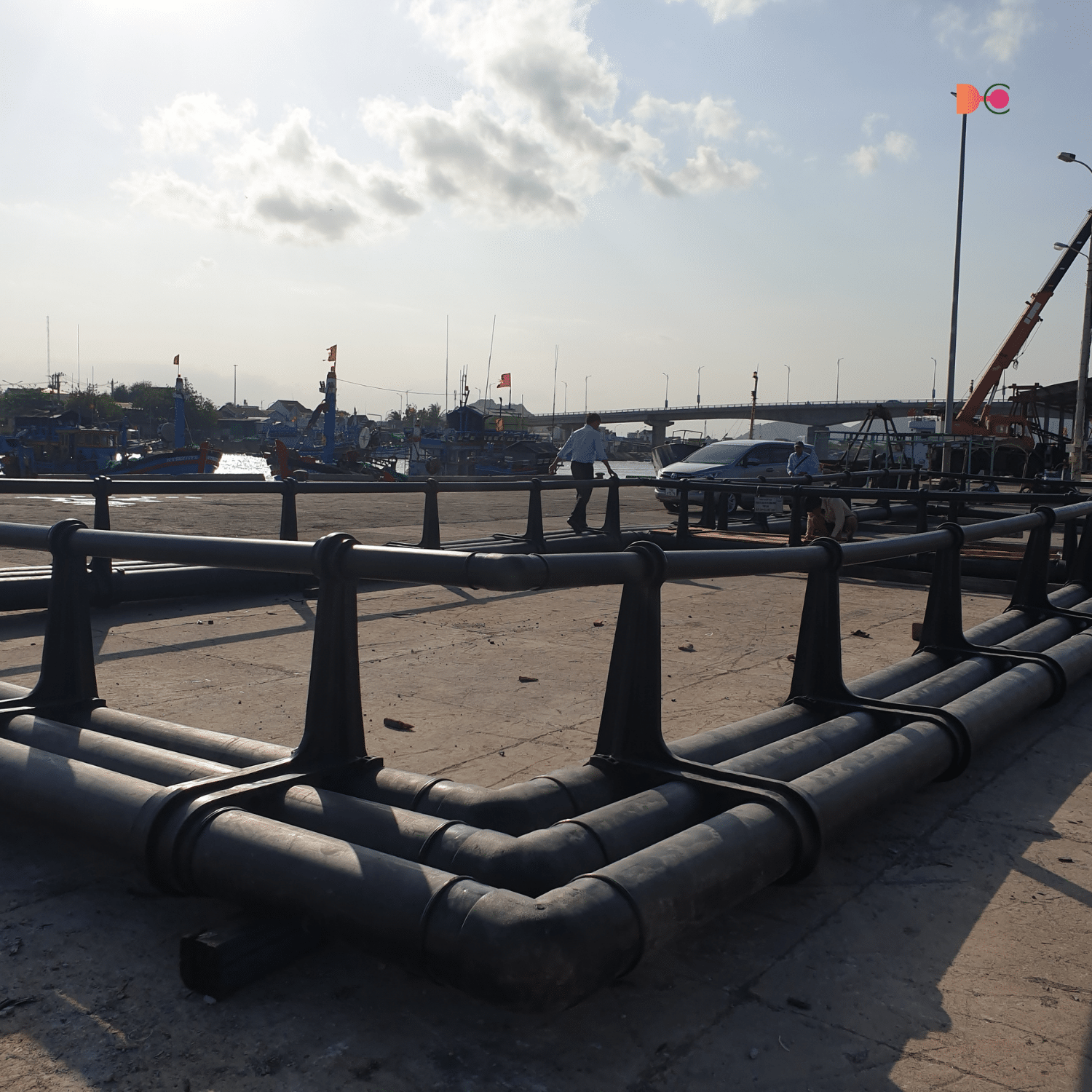

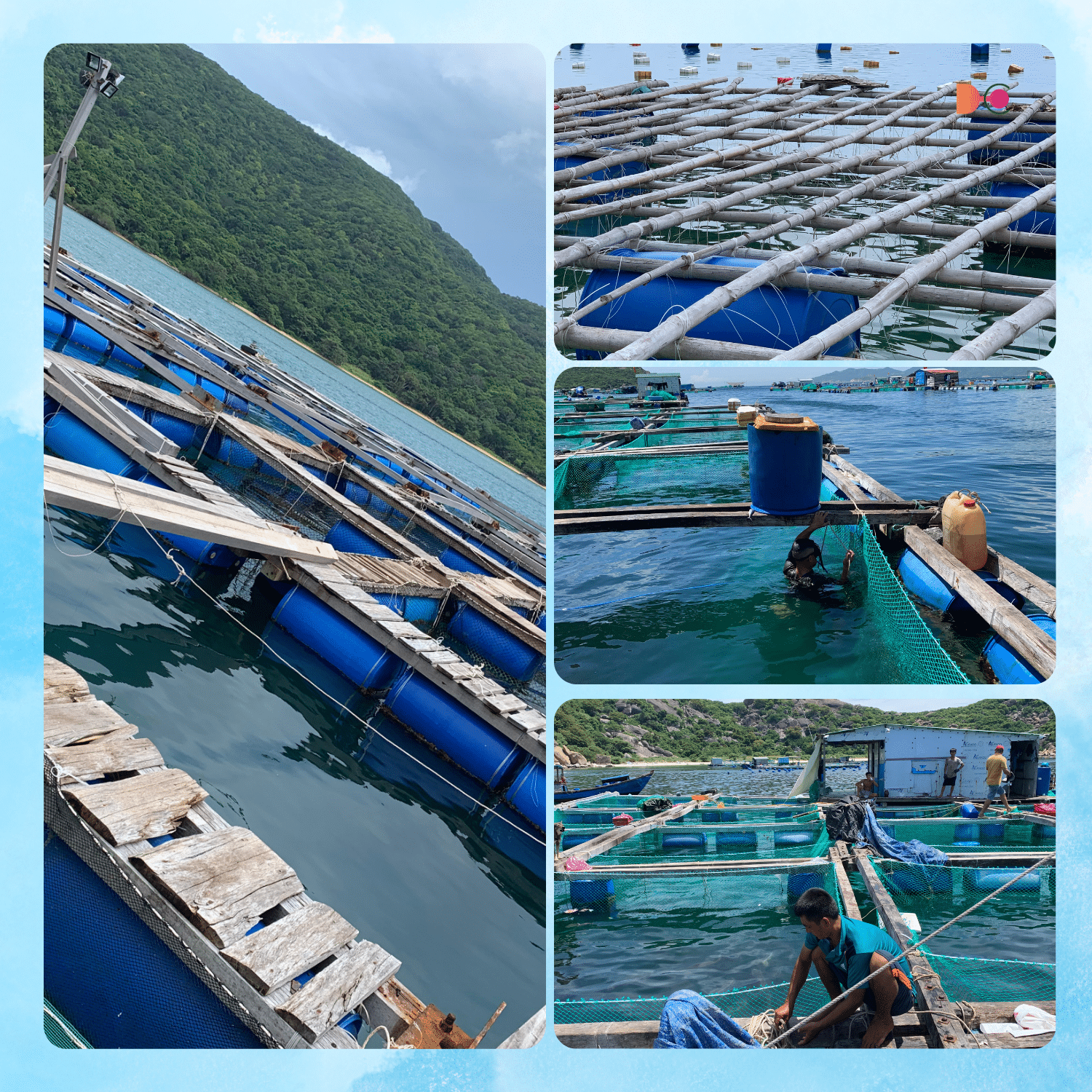

Traditional rafts are still a popular choice for farmers due to their low cost and ease of access. However, the limitations of this model are becoming increasingly apparent:

- Short lifespan: Bamboo rafts can only be used for 6 months to 1 year before they break down.

- Natural disaster risk: Loose structures cannot withstand strong storms and winds, causing heavy damage.

- Environmental pollution: Fragile styrofoam buoys create microplastics, seriously polluting the sea.

On the contrary, HDPE cages have many outstanding advantages:

- High durability: Lifespan up to 15-20 years, withstand harsh sea conditions.

- Safety, stability: Sturdy design, minimizing risks during storms.

- Environmental protection: No pollution thanks to sustainable and recyclable materials.

However, high costs are the biggest barrier that makes people hesitate to switch.

Doanh nghiệp cần làm gì để thúc đẩy chuyển đổi?

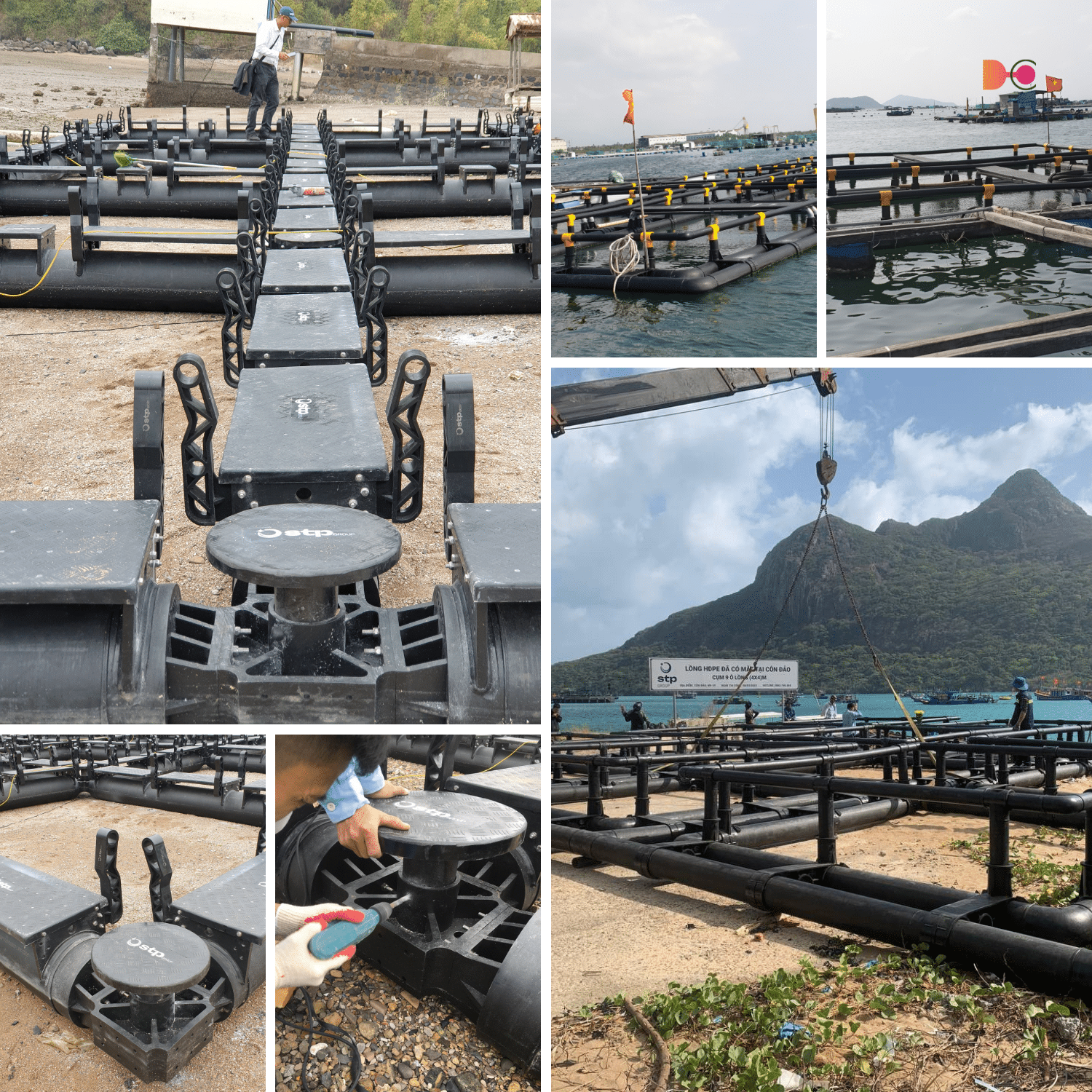

Supply chain integration to reduce costs

The high cost of producing HDPE cages is partly due to the fact that materials such as plastic pipes and outdoor plastic panels are mainly imported or produced in small orders. If large plastic manufacturers in Vietnam such as Hoa Sen, Tien Phong, and STP join together to build a complete ecosystem, costs will be significantly reduced thanks to:

- Mass production: Increasing production scale helps reduce costs.

- Localization of materials: Proactively using domestic supply to replace imported goods.

- Optimizing the process: Close cooperation from production to transportation helps reduce intermediate costs.

Providing flexible financial solutionsh linh hoạt

Enterprises can cooperate with credit institutions to implement financial support programs for people:

- Long-term installment payment: Help people access HDPE cages without having to invest heavily from the beginning.

- Loan interest support: Reduce financial pressure, create motivation for conversion.

Building pilot models and technology transfer

Large enterprises need to coordinate with local authorities to deploy HDPE cage pilot models:

- Real-life modeling: Build trust with local people through experimental results.

- Technical transfer: Instructions for installation, operation and maintenance of HDPE cages.

- Initial support: Enterprises can provide cages at preferential prices to pioneer households.

Flexible product development according to needs

Not all farmers need to invest in HDPE cages immediately. Businesses can design flexible solutions:

- Modular HDPE cages: Allow farmers to gradually upgrade from traditional cages to HDPE cages.

- Combined materials: Use HDPE for the main load-bearing parts combined with cheaper materials for the auxiliary parts.

What is the way forward?

Converting to HDPE cages is an inevitable trend for sustainable marine aquaculture development. However, to promote this process, the cooperation of businesses, authorities and fishermen is needed:

- Enterprises: Proactively invest in research, reduce costs, and provide financial support solutions.

- Government: Issue preferential policies to support people in accessing capital.

- Pioneers: Large-scale farming households boldly invest and set up models to replicate.

If all parties work together, HDPE cages will no longer be a difficult problem, but will become the door opening a sustainable future for Vietnam’s marine aquaculture industry.