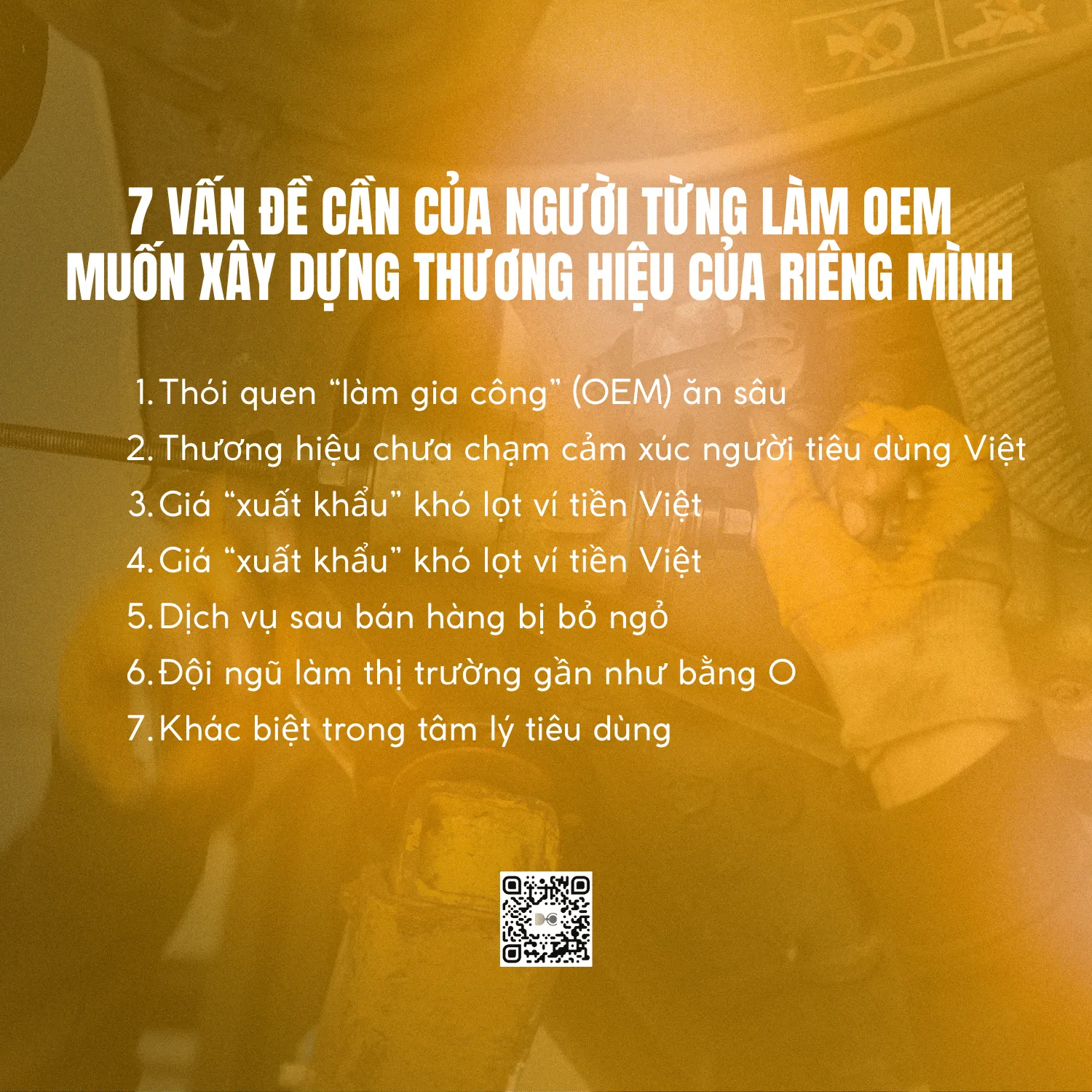

Thousands of Vietnamese factories are producing according to international standards, achieving ISO, CE, FDA, HACCP certifications, etc., and processing (OEM) for famous global brands. However, when selling their products in the domestic market, many owners “stumble”. Why can we conquer the US, EU, and Japanese markets, but find it difficult to convince Vietnamese consumers?

The habit of “OEM” is deeply ingrained

Most OEM factory owners are used to following orders from foreign customers: they send designs, specifications, standards, and we just have to produce according to the requirements. This makes us accustomed to the production mindset without forming a market mindset.

When moving to domestic sales, everything changes: there are no more “ready-made” orders, but you have to learn about demand, consumer habits, pricing methods, and distribution channels yourself. If you don’t change your mindset, it will be difficult for your products to compete, even if they are of high quality.

Brands that have not touched the emotions of Vietnamese consumers

Vietnamese people do not buy products just because they meet EU or FDA standards, they buy them because they find them suitable and worth the money. But many factory owners still maintain the same “technical” communication style as selling to international customers: listing standards, processes, and technologies.

Meanwhile, the domestic market requires a familiar brand story: what problem does this product solve, how does it make life more convenient, and what feeling does it bring when used.

“Export” prices are hard to fit into Vietnamese wallets

Products that meet international standards often have high production costs: raw materials, processes, inspections, machine depreciation, etc. When sold abroad, high prices are not a problem because they are willing to pay. But in Vietnam, in the same segment, consumers compare with lower-priced domestic products or competitively priced imported products.

If the design, packaging, and features are not optimized to reduce costs to suit average incomes, the product will be difficult to sell in large quantities.

Domestic distribution channels are complex and costly

Unlike selling to a few large customers abroad, selling in Vietnam requires opening many channels: supermarkets, agents, stores, e-commerce… Each channel requires discounts, display fees, promotions, sales staff, delivery.

Without a clear financial plan, profits will erode quickly. This is why many factory owners try selling domestically for a few months and then give up.

After-sales service is neglected

In the international market, OEMs only deliver to partners, and the warranty and customer care are the responsibility of that brand. But when selling domestically under their own brand, after-sales service becomes a vital factor.

Vietnamese customers value quick returns, clear warranties, and timely technical support. Without this system, a brand can easily lose its reputation even if the product is of good quality.

The marketing team is almost zero

Many factory owners only have production, accounting, warehouse departments… but no marketing, trade marketing, or sales teams. Meanwhile, domestic retail is a “game” for the marketing team: from consumer research, building communication campaigns, to implementing multi-channel sales.

Without the right people, any sales plan will be difficult to realize.

Differences in consumer psychology

A little-known fact: Vietnamese people often value international brands more than Vietnamese brands, even if the products are “made in Vietnam” and meet export standards. This creates a psychological barrier, making it difficult for Vietnamese products to compete at home.

To overcome this, factory owners need to invest in building a long-term reputation, and cannot rely on “selling cheaply to get quantity”.

The way to “escape the OEM fate” and conquer the domestic market

- Thorough market research: Understand the needs, acceptable prices, and shopping habits of each Vietnamese customer group.

- Appropriate product design: Can maintain core quality, but optimize packaging, features, and size to reduce costs.

- Building a strong Vietnamese brand: Tell a close story, appeal to emotions and practical benefits.

- Prepare diverse distribution channels: Offline, online, agents, supermarkets, e-commerce platforms.

- Invest in after-sales services: Warranty, return, and technical support systems.

- Recruit or cooperate with a professional sales and marketing team: Cannot do it all by yourself.

Conclusion

Being a good OEM for international brands is a great foundation, but to be successful in the domestic market, Vietnamese factory owners need a completely different “skill set”. When we have an international standard factory and know how to build a brand and sales system in Vietnam, we will not only live on outsourcing but also make money from our own Vietnamese brand.