HDPE cages are gradually replacing traditional cages thanks to their high durability and environmental friendliness. However, from a technical perspective, each HDPE cage model has its own advantages and disadvantages. Some benefits have been clearly demonstrated, but there are also many technical issues that need to be further monitored and evaluated.

Popular HDPE Raft Cage Models

Currently, HDPE cages have many different designs, depending on the scale of farming and marine environmental conditions:

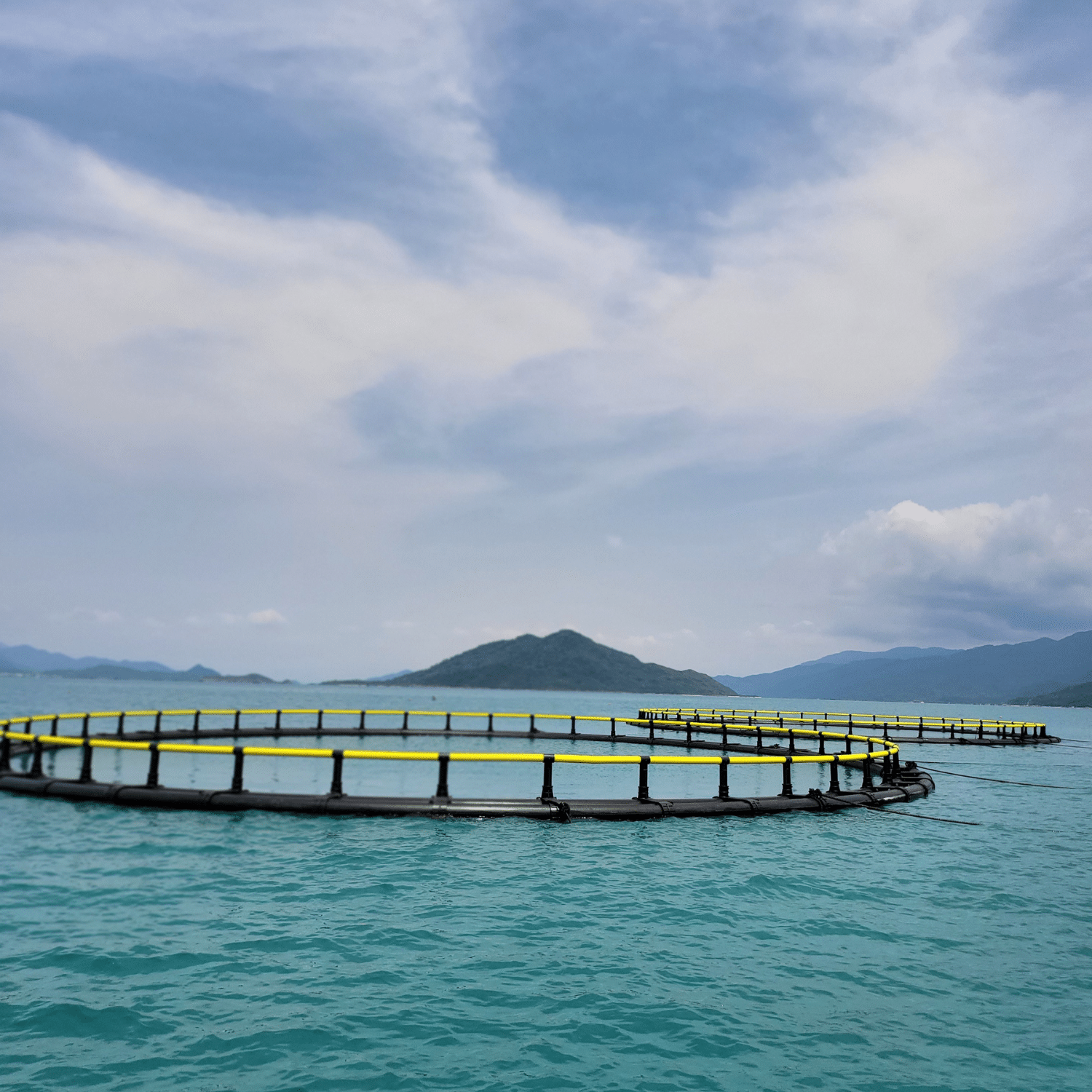

Circular Cage:

- Description: Circular in shape with a diameter of 10-30m, the cage frame is made of high-strength HDPE pipes, suitable for offshore areas.

- Advantages: Withstands large waves (over 5m), high durability, optimal design helps good water circulation, reduces diseases for seafood.

- Disadvantages: High investment cost, difficult to maintain when there is a problem and requires complex operating techniques.

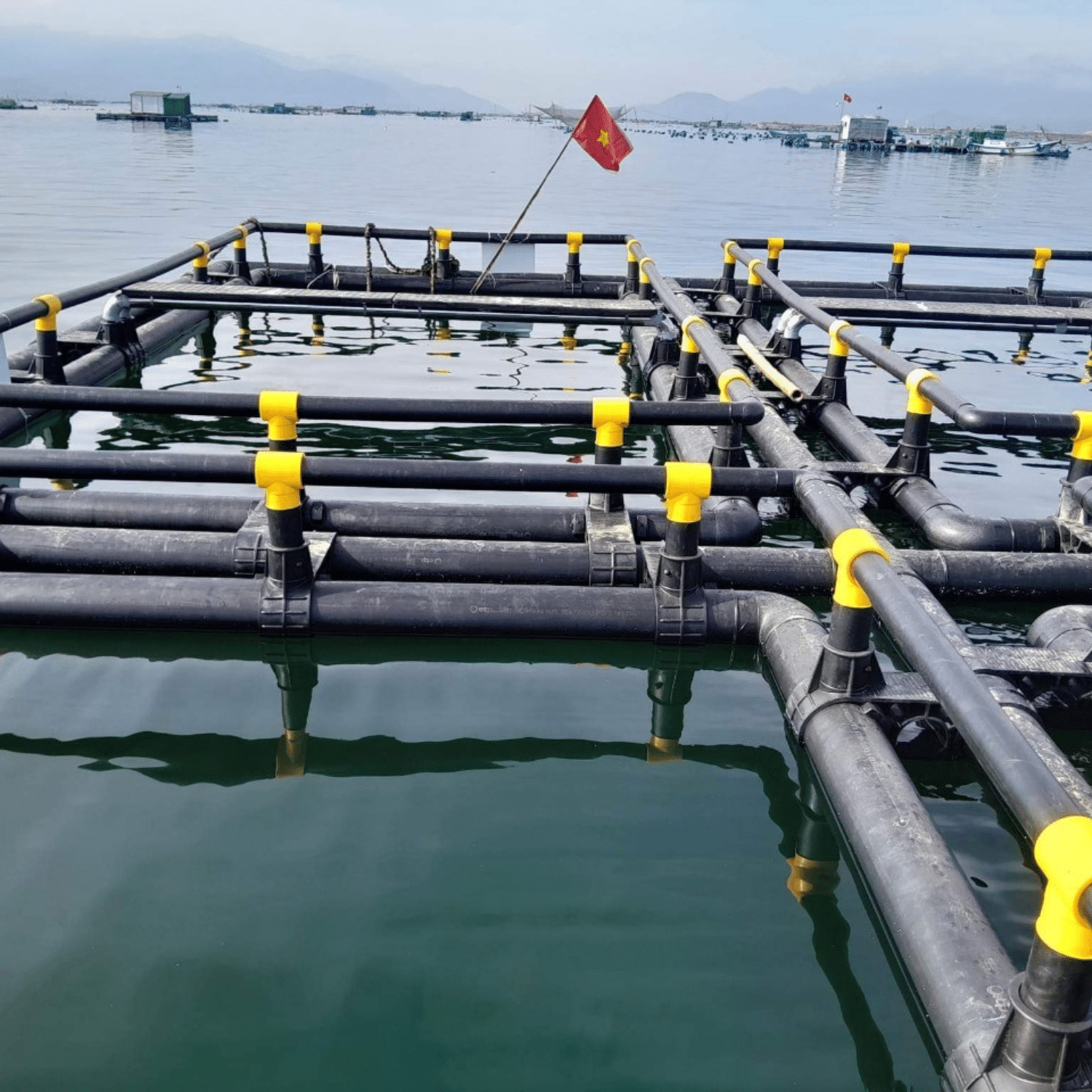

Square Cage:

- Description: Square or rectangular in shape, often used for coastal areas, common size 3x3m or 5x5m.

- Advantages: Simple installation, lower cost than round cages, easy to check and harvest.

- Disadvantages: Less wind and wave resistance, more suitable for calm waters.

Submersible Cage:

- Description: Can adjust the buoyancy according to weather conditions, helping to protect aquatic products in harsh environments.

- Advantages: Withstands large storms, protects fish from predators, minimizes damage when the sea is rough.

- Disadvantages: Complex buoyancy mechanism, very high investment and maintenance costs.

Proven Advantages of HDPE Cages

- High durability: HDPE is UV-resistant, salt-resistant and corrosion-resistant, allowing cages to be used for over 15 years without replacement.

- Adapting to harsh environments: HDPE cage models, especially round cages and semi-submersible cages, can withstand level 8-9 winds and waves, suitable for offshore waters.

- Reduced maintenance costs: Compared to wooden or iron cages, HDPE cages are less prone to damage, do not require anti-rust paint or frequent replacement.

- Environmentally friendly: Does not cause microplastic pollution, does not rot like wooden cages, helping to protect the marine ecosystem.

Unresolved Technical Issues

- Long-term stability under deep-sea pressure:

- .Although short-term tests have shown that HDPE cages can withstand high pressures, there is insufficient data to assess the ability of the structure to maintain its structure when operating continuously at depths above 30m.

- Impact on marine life

- The use of large-scale HDPE cages can change local flows and ecological environments. Currently, there are no long-term studies that have fully assessed this impact.

- Recyclability and end-of-life treatment:

- HDPE is recyclable, but the collection and treatment of cages after use has not been implemented synchronously, especially in offshore farming areas.

- Agricultural performance in extreme conditions:

- Although semi-submersible cages help protect seafood from strong storms, there is not enough data to prove the long-term effectiveness of this model under continuous natural disasters.

Future Directions for Technical Improvement

To make HDPE cages a more sustainable solution for marine aquaculture, further improvements and research are needed:

- Development of new generation HDPE materials: Enhanced resistance to deep sea pressure, extended life and reduced production costs.

- Improved cage design: Smarter design to optimize water circulation, limit organic waste accumulation, reduce disease risk.

- Smart monitoring system: Combining sensors to monitor water quality, cage structure and aquatic health to help farmers better control and intervene promptly.

- Take-back and recycling program: Develop a process to take back HDPE cages at the end of their life cycle, promoting a circular economy in the marine aquaculture industry.

Conclusion

HDPE cages offer many outstanding benefits for sustainable marine aquaculture, but there are still technical issues that have not been thoroughly resolved. Continued research, improvement and long-term evaluation are necessary to maximize the effectiveness and minimize risks when applying this model in marine aquaculture practice.